Understanding the High-Performance Heat-Resistant Laser Ceramic Ring

The High-Performance Heat-Resistant Laser Ceramic Ring is an essential component for industrial laser systems, designed to withstand extreme thermal conditions without compromising performance. Made from advanced ceramic materials, this ring is engineered to address the challenges of heat-intensive laser operations, where standard components often fail due to thermal stress. It acts as a protective and functional element, ensuring stable signal transmission and precise alignment in laser machines. Unlike conventional metal or plastic rings, the ceramic construction offers superior heat resistance, making it a reliable choice for continuous industrial use. This ring is not just a passive component but an active contributor to the efficiency and longevity of laser systems, ensuring consistent performance even in the most demanding environments.

Properties of Heat-Resistant Ceramic

The core of this ring’s performance lies in its high-quality ceramic material. Ceramic is naturally resistant to high temperatures, allowing the ring to maintain its structural integrity even when exposed to extreme heat generated by laser cutting, welding, or engraving. Additionally, the material offers excellent thermal stability, meaning it does not expand or contract significantly under temperature fluctuations. This stability ensures that the ring retains its shape and alignment, preventing signal disruptions and misalignment that can affect laser precision. The ceramic material also boasts high sensitivity, enhancing signal transmission for more accurate laser operations.

Typical Uses of the Laser Ceramic Ring

Laser Cutting and Welding Operations

In laser cutting and welding applications, the High-Performance Heat-Resistant Laser Ceramic Ring is indispensable. It withstands the intense heat generated during these processes, ensuring that the laser system maintains consistent performance. In cutting operations, the ring helps stabilize the laser beam, resulting in clean, precise cuts without burrs or irregularities. For welding, it ensures that the laser focus remains accurate, producing strong, uniform welds that meet industrial standards. Its ability to resist thermal stress reduces the need for frequent replacements, minimizing downtime in production lines and boosting overall efficiency.

Industrial Engraving and Processing

The ring also plays a crucial role in high-heat laser engraving tasks. Whether engraving on metal components or heat-sensitive materials, it maintains stable signal transmission, ensuring that every detail of the engraving is captured accurately. It is widely used in industries such as automotive, aerospace, and electronics, where precision engraving of serial numbers, logos, and other identifiers is required. The ring’s durability and heat resistance make it suitable for continuous use in high-volume engraving operations, where reliability and consistency are key to meeting production targets.

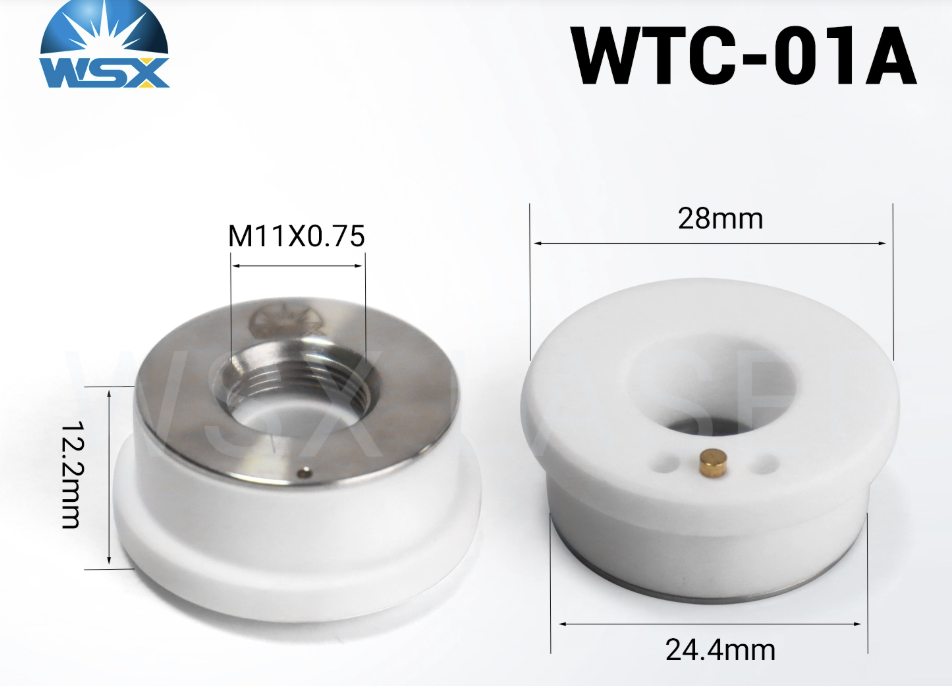

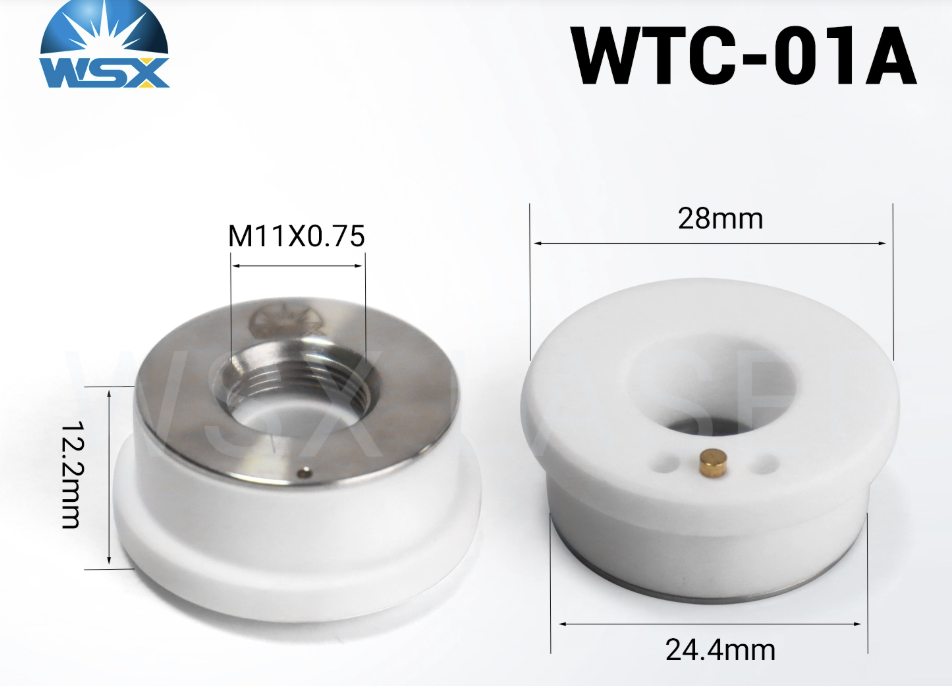

Design Specifications

Material and Construction

The High-Performance Heat-Resistant Laser Ceramic Ring is constructed from high-performance, heat-resistant ceramic that is carefully selected for its durability and thermal properties. The ceramic is processed using advanced manufacturing techniques to ensure a smooth, precise surface that facilitates optimal signal transmission and alignment. The ring features a precision-engineered design with strict tolerances, ensuring a perfect fit in most industrial laser systems. Its robust construction resists wear and tear, even in environments with constant vibration and exposure to dust and debris. The ceramic material also prevents bursting, a common issue with low-quality rings that can lead to costly equipment damage.

Compatibility and Installation

Designed for versatility, the ring is available in various sizes to accommodate the specific requirements of different laser systems. It features a user-friendly design that allows for easy installation, requiring no specialized tools or technical expertise. The ring’s threaded design ensures a secure fit, preventing movement during operation that could compromise precision. Its compatibility with a wide range of laser machines, including cutting, welding, and engraving systems, makes it a versatile component that can be integrated into existing setups with minimal effort. The compact size of the ring also ensures that it does not interfere with other components of the laser system.

FAQ About the Laser Ceramic Ring

Heat Resistance Capabilities

Q: How does the High-Performance Heat-Resistant Laser Ceramic Ring perform in extreme heat conditions?

A: The ring is specifically engineered to operate effectively in extreme heat environments. Its high-performance ceramic material resists thermal stress and maintains structural integrity even at elevated temperatures, ensuring consistent performance without degradation. It is designed to withstand the heat generated by continuous laser operations, making it ideal for heat-intensive industrial applications.

Replacement and Lifespan

Q: How often should the ceramic ring be replaced?

A: The lifespan of the ring depends on usage conditions, but its durable ceramic construction ensures long-term performance. With proper maintenance, including regular cleaning to remove dust and debris, it can last for an extended period. Unlike standard rings that require frequent replacements due to thermal damage, this ceramic ring minimizes downtime and reduces replacement costs, making it a cost-effective choice for industrial users.

Signal Stability Benefits

Q: How does the ring enhance signal stability in laser systems?

A: The ring’s high-sensitivity ceramic material and precision engineering ensure stable signal transmission. It minimizes signal loss and interference, even in high-heat environments, allowing the laser system to maintain accurate alignment and focus. This stability translates to more consistent and reliable laser operations, reducing errors and improving the quality of the final product.