A protective lens helps your laser last longer. It stops dust and dirt before they touch the optics. In busy factories, you face problems like dirt buildup. Overheating and laser failure can also happen.

Protective lenses help your system work well.

Dirt and damage can make it too hot and work worse.

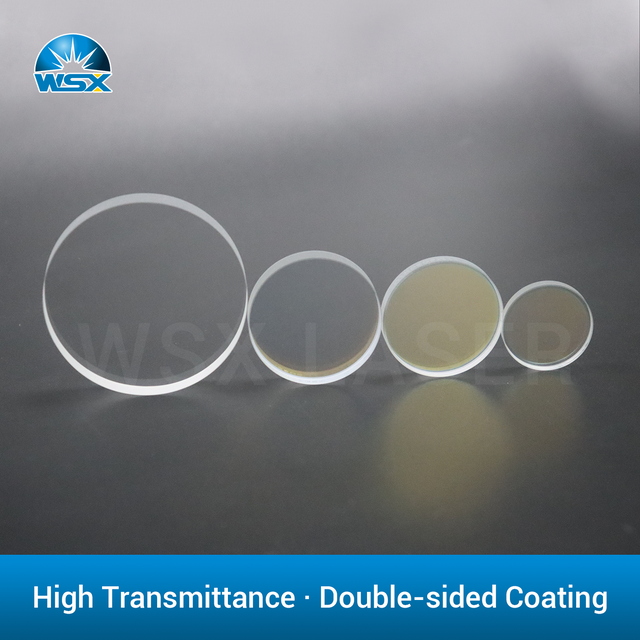

Special protection windows, like the WSX lens, help keep your machine safe and running smoothly.

Key Takeaways

A protective lens works like a shield. It stops dust and dirt from reaching your laser optics. This helps your laser stay clean and last longer.

You need to take care of the lens often. Clean it and change it when needed. This helps your laser work well for a long time.

Good protective lenses, like the WSX lens, can help you save money. They lower repair costs and reduce the time your laser is not working.

Always wear safety glasses when you touch or clean your laser lens. This keeps your eyes safe from harm.

Pick the right lens material and coating for your laser type. This makes your laser work better and keeps your work quality steady.

Protective Lens Function

Blocks Debris

Industrial laser work has many problems. One big problem is debris. When you cut or weld with lasers, small bits like weld spatter and dust go into the air. These bits can land on your laser optics and cause problems. A protective lens works like a shield. It stops debris, splatter, and other dirty things before they touch the important parts of your laser system. This keeps your optics clean. It helps your laser work well for a longer time.

Tip: Always look at your lens material after each job. If you see buildup, clean it. Clean lenses help your laser work better.

Prevents Damage

If your laser optics get damaged, your work can stop. This can cost you money. You need to keep your equipment safe from scratches, heat, and chemicals. Picking the right lens material is very important. Good coatings on the lens material help stop heat from causing cracks or other problems. In places like factories, labs, and hospitals, you must use protective lenses to keep your laser safe.

Laser eye protection is needed for strong lasers to stop injuries.

Pick the right lens material and coating for your laser’s power and wavelength.

Check and clean your protective lens often so it works well.

The WSX Protective Lens has strong coatings and tough lens material. This design helps stop damage from heat and debris, even in busy places.

Reduces Wear

Lasers in factories work hard every day. Over time, normal use can wear out your optics. A protective lens takes the hit from dust, splatter, and heat. This means you do not need to change your main optics as much. It saves you time and money.

Here is how a protective lens helps you:

Benefit | Description |

Enhanced Performance | More laser energy gets to your work, so you get better results. |

Increased Durability | The lens material fights scratches and heat, so it lasts longer. |

Cost-Effectiveness | You spend less on repairs and new parts, so you save money. |

The WSX Protective Lens is known for being tough. Users say its lens material and coatings last longer, even in dusty or busy places. Some people have fewer stops for fixing and less downtime. This means your laser can keep working without many repairs.

Note: Pick the right lens material and change your protective lens on time. This helps your laser system last longer and work better.

Benefits of Protective Lens

Longer Laser Life

You want your laser system to last as long as possible. A protective lens helps you reach that goal. It acts as a clear shield that blocks dust, smoke, and other particles from reaching the sensitive parts inside your laser. When you keep these contaminants away, your laser optics stay clean and work better for longer. This means your machine can keep running strong, even after many hours of use. You avoid problems like dirty optics or damaged parts, which can shorten the life of your laser. By using a protective lens, you help your laser system stay in top shape and avoid early breakdowns.

Consistent Quality

You need your laser to deliver the same high-quality results every time. A protective lens makes this possible. It keeps the laser beam focused and precise by stopping dust, smoke, and splashes from interfering with the optics. When your lens stays clean, your cuts and engravings look sharp and detailed. You get smooth edges and clear lines, whether you work with metal, plastic, or other materials. The right lens also helps control heat, so your workpieces do not get burned or warped. With a protective lens, you can trust your laser to give you great results on every job.

Tip: Choose the right lens for your material and application. This helps you get the best performance from your laser cutter or engraver.

Lower Costs

You save money when you use a protective lens. It protects your laser’s expensive parts, so you do not need to repair or replace them as often. Less downtime means you can finish more jobs and keep your business running smoothly. You also spend less on new parts because your main optics last longer. The WSX Protective Lens stands out because it lasts a long time and is easy to replace. You can swap it quickly, which keeps your machine working and reduces lost time.

Feature | Description |

Long Service Life | You change lenses less often, so you spend less on maintenance and keep your laser running. |

Durable Construction | The lens stands up to tough conditions, protecting your laser from damage. |

Easy Installation | You can install the lens fast, so you get back to work with little delay. |

A WSX laser head can last for many years if you take care of it. Even if the initial cost is higher, you save money over time because you do not need to buy new lenses as often. This makes the WSX Protective Lens a smart choice for anyone who wants to protect their investment and keep costs low.

Maintenance Tips

Install Properly

You need to install your protective lens the right way to get the best results. Always wear safety glasses before you start. Safety glasses protect your eyes from dust and small particles. When you handle the lens, use clean gloves and avoid touching the surface. Place the lens gently into the holder. Make sure it sits flat and tight. If you use WSX lenses, you will notice the design makes installation quick. The lens fits perfectly, so you spend less time on setup. Safety glasses should stay on during the whole process. You should also check that your protective eyewear fits well and covers your eyes fully.

Tip: Double-check the lens position before you power up your laser. Safety glasses are important every time you work with lasers.

Clean Regularly

Keeping your lens clean helps your laser work better. You should always wear safety glasses when cleaning. Clean your lens every week to stop dust from building up. Before you start, inspect the lens for dirt or smudges. Use safety glasses to protect your eyes from cleaning sprays or flying dust. Follow these steps for the best results:

Use an air ball to blow off loose dust. Do not use compressed air.

Dip a cotton ball in almost pure acetone. Wipe the lens in small circles.

If dirt stays, rinse with diluted vinegar, then clean again with acetone.

For polishing, use a fine aluminum paste and a cotton ball. Rinse with distilled water.

Finish by wiping with isopropyl ethanol to remove any leftover marks.

If you see sticky spots, clean them right away. Always use safety glasses during each step. Durable safety eyewear keeps your eyes safe from chemicals and dust.

Note: Wipe the lens gently with a lint-free cloth or lens cleaning wipe. Safety glasses are a must for every cleaning session.

Replace Timely

You should replace your protective lens on time to keep your laser working well. In busy factories, change the lens every 1-3 years. The timing depends on how much you use your laser and what materials you cut. Regular replacement keeps your cuts sharp and your machine safe. Always wear safety glasses when you remove or install a lens. Safety glasses protect you from broken glass or dust.

The WSX Protective Lens makes replacement easy. You can change the lens in just a few minutes. This fast process means you do not lose much work time. The table below shows how WSX lenses help you save time:

Evidence Description | Impact on Production Downtime |

Quick and easy lens changes | Minimizes long interruptions, ensuring efficiency |

Optimized lens assembly design | Allows lens replacement in minutes, reducing downtime |

Alert: Never skip safety glasses when replacing lenses. Safety glasses are your first line of defense.

You should always keep extra lenses and safety glasses nearby. This way, you can replace a lens quickly and get back to work. Safety glasses help you stay safe every time you handle your laser system.

Common Mistakes

Low-Quality Lenses

Some people think any lens will work. But using low-quality lenses can hurt your laser system. These lenses soak up more laser light. This makes the lens get too hot. When this happens, the laser focus gets messed up. Your cutting quality gets worse. Bad lenses also do not stop dust and spatter. Burn spots can show up on your lens. Sometimes, debris piles up and harms the focusing lens. You might have to change the whole part. If the protective lens breaks, it can even damage the laser source head and output window.

The thermal lens effect makes the lens too hot and focus poorly.

Bad lenses let dust and spatter in, causing burn spots.

Debris can hurt the focusing lens and laser head.

Picking high-quality lenses helps you avoid these problems. It keeps your laser working longer.

Skipping Maintenance

Not doing regular maintenance is another big mistake. It can waste your time and money. Even a little dirt can lower your laser’s power by 10–30%. This means your results will not always be the same. If you skip maintenance, your laser might break without warning. Repairs can take days and cost a lot of money. Broken lasers can also be unsafe. They can send out dangerous radiation that burns or hurts your eyes.

Consequence | Description |

Performance Degradation | A little dirt can cut laser power by 10–30%. This gives you uneven results. |

Increased Downtime | Sudden failures can need 2–7 days to fix. This can cost $50,000–$200,000 each day in lost work. |

Safety Risks | Broken lasers can send out unsafe radiation. This can cause burns or eye injuries. |

If you do not clean and check your laser, you can get uneven cuts. You might waste material and overheat your machine. These problems make your equipment wear out faster and make your work less safe.

Ignoring Safety Glasses

Never forget to wear safety glasses when using lasers. Safety glasses keep your eyes safe from laser radiation. Laser radiation can cause blindness or permanent eye damage. You must pick safety glasses with the right optical density for your laser’s wavelength. Take away shiny things before you start. Reflections can also hurt your eyes. Touching the laser beam, even by accident, can cause bad injuries.

The ANSI/ISEA Z87.1-2020 standard tells you how safety glasses should protect you. Real stories show what happens if you skip safety glasses:

Year | Incident Description | Outcome |

1992 | A research assistant hurt both eyes with a laser and no safety eyewear. | Sued the university for $39 million, settled for $1 million. |

1988 | A technician got laser light in the eye with no protection because goggles were foggy. | Got a permanent blind spot. |

N/A | A technician took off eye protection and got hit by a stray reflection. | Lost part of his vision. |

You can lose your vision in just seconds. Always wear safety glasses and check if they are still strong before each use. Good safety glasses last longer and protect you better. Strong safety glasses are important in busy places. Make safety glasses a habit every time you use lasers.

You can make your laser last longer and work better by using protective lenses like the WSX Protective Lens. You should always wear safety glasses when you handle or clean your lens. Safety glasses help protect your vision from dust and laser light. Experts say you need to:

Wear safety glasses every time you change, clean, or inspect your lens.

Use safety glasses that fit well and match your laser’s wavelength.

Check that your safety glasses have side shields and clear labels.

Clean your lens in a dust-free place while wearing safety glasses.

Replace your safety glasses if they get scratched or damaged.