When you pick a Fiber Laser Head for work, look for these key features: power, auto-focus, cooling, motion dynamics, and automation compatibility. Each feature helps the machine work better and last longer. For example, WSX models use special cooling to stop overheating and auto-focus to make cuts more exact. The table below shows how these features help performance:

Feature | Impact on Productivity and Reliability |

Power | Clean work with less heat damage |

Auto-focus | Accurate work and high-quality results |

Cooling | Steady work during long jobs |

Motion Dynamics | Exact work on hard tasks and steady quality |

Automation Compatibility | Fast, mistake-free work with smart controls |

Key Takeaways

Pick a Fiber Laser Head with important features like power, auto-focus, and cooling. These help make work faster and more reliable.

Look for models with good cooling systems. This stops the machine from getting too hot. It helps the laser work well for a long time.

Choose a laser head that works with automation. This makes jobs easier and helps avoid mistakes.

Find designs that are easy to take care of. This means less time fixing things and more time working.

Always check for safety features and rules. This keeps workers safe and the workplace secure.

Selection Importance

Productivity Impact

Picking the right Fiber Laser Head helps you work faster. It also makes your work more exact. Good equipment gives better results and saves time. Many companies use fiber lasers now. They like them because they are small and flexible. These lasers help in electronics and medical device making. They are great for jobs that need tiny cuts.

Fiber lasers are taking the place of older ways like chemical etching and solid-state laser cutting.

You can cut thin sheets easily. This helps with the need for quick and clean work.

The right laser head lets you work with many materials and thicknesses. You do not have to stop and change tools.

If you choose the wrong laser head, problems can happen. You might lose energy or get bad cuts. For example:

The wrong nozzle wastes energy and makes cutting harder.

A nozzle that is too small gets very hot and can hurt the cutting head.

If the focal length does not fit the material, you may see rough edges or burrs.

Tip: Always pick laser head features that match your job. This helps you work better and avoid mistakes that cost money.

Reliability Factors

You want your machine to last and work well every day. The design and features of the laser head matter a lot. Check the table below to see what helps with reliability:

Reliability Factor | Description |

Optical Components | Good optics give you a strong beam and exact cuts. |

Cooling Systems | Cooling keeps parts from getting too hot and helps them last longer. |

Construction of the Head | A strong build means you fix it less and it lasts longer. |

Nozzle Design | The right nozzle size and shape help clear away material. |

Focusing Lens | The right lens lets you cut different thicknesses well. |

Protective Mirrors | Clean mirrors keep the beam strong and help the head last. |

Height Adjustment Sensors | These sensors keep the focus steady and stop damage. |

Ceramic Body | Ceramic parts protect from heat and make the head stronger. |

When you pick a laser head with these features, you have less downtime. Your work keeps going smoothly.

Fiber Laser Head Features

Laser Power

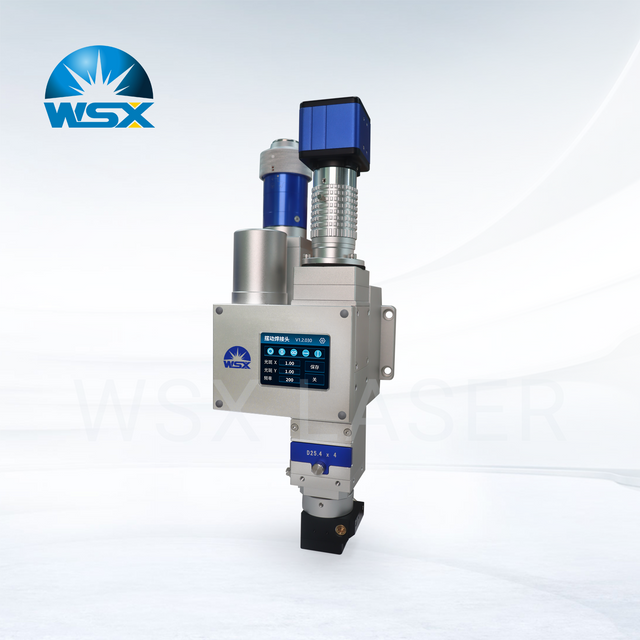

Laser power is important when picking a Fiber Laser Head. More power lets you cut thicker things and work faster. The WSX ND31A model can go up to 4000W. This is good for welding plates that are not too thin. The HB15 model has 3000W. It works well for aluminum and welding with medium power. Other brands, like IPG Photonics and Coherent, have even more power. Some can reach 30 kW or higher.

Laser Power (W) | Max Material Thickness | Cutting Speed |

1000 | Thin sheets | Slow |

3000 | Medium plates | Medium |

6000+ | Thick plates | Fast |

If you use more power, you cut faster. This helps you finish jobs quickly and work with more materials. High-pressure nitrogen helps you cut thick things with smooth edges.

Beam Quality

Beam quality decides how neat your cuts and welds look. A good Fiber Laser Head gives a sharp and steady beam. WSX NC36 and NC65 models focus on high beam quality. They work for both thin and thick materials. If your laser head tunes the beam well, you get smooth edges. Even thick pieces look better.

Feature | Impact on Precision |

Beam diameter and shape tuning | Better edge quality |

Rapid beam tuning | High precision for all jobs |

Consistent beam across thicknesses | Reliable results |

Narrow, high-aspect-ratio features | Precise corners and details |

You will notice your finished parts look cleaner. Good beam quality means fewer rough spots and sharp corners. This is important for electronics and cars.

Auto-Focus

Auto-focus helps you save time and avoid mistakes. The WSX NC65 model uses auto-focus to move the laser in real time. You do not need to stop and change settings for different thicknesses. This keeps your cuts steady and setup time short.

Auto-focus changes the focus fast, so you do not waste time.

You get smooth, straight edges with fewer rough spots.

Your work stays the same, even with small batches or many types.

Auto-focus helps you keep working and get good results.

Cooling System

A strong cooling system helps your Fiber Laser Head last longer. WSX models use smart cooling to stop overheating. Chiller units and TECs keep the temperature right. Some systems use smart controls to change cooling as needed.

Chiller units help laser parts last longer.

TECs are quiet and fit in small places.

Self-cooling designs make fixing things easier.

Recirculating chillers save energy and help the planet.

A good cooling system gives you better beams and longer-lasting tools.

Motion Dynamics

Motion dynamics control how the laser head moves. The WSX SW30 model can cut pipes in three dimensions. Smart motion control helps you work on hard shapes and keep cuts neat. Height sensors and dynamic controls move the laser in real time.

Motion Feature | Benefit |

Efficient motion control | Precise 5-axis cutting |

Dynamic control | Accurate, fast adjustments |

Height sensors | Steady focus on all materials |

You can do hard jobs and keep your work neat. Good motion dynamics mean you finish more work and waste less.

Note: WSX has many models, like ND31A, HB15, SW30, NC36, and NC65. You can pick the best Fiber Laser Head for your job. Features like beam quality, saving energy, and easy design help you work better and spend less. Many workers like easy fixes, built-in lights, and smart checks. These make daily work easier and more dependable.

Automation Compatibility

Integration

You want your Fiber Laser Head to work well with other machines. Good integration helps you connect it to robots and conveyors. This makes your factory run faster and better. Advanced software gives you more control and features. Automated material handling moves parts without stopping work. This means less downtime and more finished products each day. Smart cutting systems lower the need for people to do things by hand. They also help you make fewer mistakes.

Advanced software lets you use your laser head in more ways.

Automated material handling keeps things moving and increases output.

Smart cutting processes help stop errors and reduce manual steps.

Sometimes, adding a new laser head can be hard. The table below shows problems and ways to fix them:

Challenge | Solution |

Gas Flow Management | Keep gas pressure and flow steady |

Customized Setup | Use special coil feeding systems |

Thermal Damage | Change cutting settings to avoid damage |

Power Drops | Use stronger cooling systems |

Operator Training | Teach your team everything they need to know |

Tip: If you plan for these problems, your factory works better and gets stronger.

Software Control

Software control helps you manage your laser head easily. Smart programs let you change settings while the machine is working. You can adjust the laser for different materials without stopping. This makes your work flexible and helps you get good results. Automating settings saves time and stops mistakes. IoT sensors watch your machine and send data to help you fix problems early.

Smart software lets you change settings fast for each job.

Automated controls for different materials save time and stop errors.

IoT sensors give you live data for checks and repairs.

You get more control and keep your machines working longer. This helps you do well in a busy factory.

Maintenance

Serviceability

You want your Fiber Laser Head to work every day. Easy serviceability means you can fix it fast. Many brands make laser heads that are simple to repair. You can check sensors and read the machine’s messages. You can also change parts without taking out the whole unit. This saves time and keeps your work going.

Troy Wilson, a product manager, says, "Fixing fiber lasers is easier than we thought. The easy checks, talking to the laser system, and changing parts when the machine is off help us keep customers working all the time."

Most fixes take less than two hours. You can do them where the machine is. You do not have to wait for long repairs. Checking and lining up parts often helps you find problems early. If you follow a plan for care, you stop big breakdowns.

Support

Good support helps you fix problems fast. You get help with setup, learning, and repairs. Many companies give you a warranty, so you feel safe if something breaks. You can call for help and get answers quickly. Some services send experts to you in one day. Remote checks let workers fix things right away.

Here is a table that shows types of help and why they matter:

Support Type | Description | Impact on User Satisfaction and Operational Continuity |

Warranty Coverage | Promise to fix broken parts or problems. | Makes you feel safe and happy. |

Installation | Experts set up your machine for best use. | Easy start and fewer problems. |

Training | Shows you how to use and care for your laser head. | Better skills and less time lost. |

Ongoing Support | Help with fixing and caring for your machine. | Fast fixes and steady work. |

Fast repairs stop your work from slowing down.

On-site help comes quickly when you need it.

Remote tools and spare parts make fixes faster.

If you pick a Fiber Laser Head with good help and easy fixes, your business runs better. You save money and do not have long stops at work.

Safety

Mechanisms

It is important to think about safety when using a Fiber Laser Head. New machines have many safety features built in. These features help keep you and your tools safe from harm. Here are some of the main safety mechanisms you might see:

Safety Mechanism | Description |

Interlocking Device | Stops the machine to keep the operator safe in certain cases. |

Emergency Stop Button | Quickly turns off the machine and power if there is danger. |

Protective Cover and Shield | Blocks laser rays and keeps workers safe from flying metal and smoke. |

Safety Warning Label | Tells workers about dangers in places like laser zones. |

Cooling System | Keeps the machine cool so it does not get too hot or break. |

Smoke and Dust Extraction System | Takes away bad smoke and dust made during cutting to keep workers healthy. |

Operator Training and Protective Equipment | Makes sure workers know what to do and wear gear like goggles and gloves. |

Always read the manual before you begin. Find the emergency stop button before you start. Keep fire extinguishers nearby and ready to use. Watch out for the laser beam and gas pipes. These steps help you stay safe and stop accidents.

Compliance

You need to follow strict rules when using laser machines at work. These rules help keep you and others safe. Many places want you to meet world safety standards. Here are some good ways to follow the rules:

Wear safety glasses, gloves, and special clothes to block laser light and dust.

Use machines with safety parts like interlocking devices and emergency stop buttons.

Go to safety classes and check your skills often.

Put up warning signs and shields in your workspace.

Take care of your machine so all safety parts work right.

Note: Following these rules keeps you safe and helps your business avoid trouble. Using a Fiber Laser Head with strong safety features makes your shop safer and helps you get more work done.

Practical Considerations

Durability

When you choose equipment for your factory, you want it to last. A strong laser head keeps your work going without many stops. Many fiber lasers use tough materials that handle long hours and heavy use. You do not have to worry about frequent breakdowns. This helps you keep up with tight schedules and avoid costly delays.

Fiber lasers use less electricity than older CO2 systems. This saves you money over time.

The design has no moving parts. You spend less time fixing things and more time working.

The machines can run for long periods without wearing out.

You get longer service intervals and lower costs for repairs compared to traditional systems.

WSX laser heads stand out because they focus on durability. Their robust build and integrated cooling systems help them work well even during long shifts. You can trust them to deliver steady results day after day.

Here is a quick look at what makes WSX heads easy to maintain:

Feature | Contribution to Low Maintenance Requirements |

Sealed Optics | Keeps dust and debris away from the lens, so you clean less often. |

Integrated Cooling | Stops overheating and helps parts last longer. |

Robust Design | Handles tough jobs and reduces how often you need repairs. |

Environmental Adaptability

Factories can be hot, cold, dusty, or humid. You need a laser head that works well in any setting. WSX designs their products to handle many types of environments. The sealed optics keep out dust and dirt. The cooling system keeps the machine at the right temperature, even when the air gets warm.

WSX laser heads stay reliable in busy, demanding places.

The strong build means you do not have to worry about bumps or vibrations.

You get stable performance, whether you cut thin sheets or thick plates.

If you want a Fiber Laser Head that keeps up with your factory’s needs, look for one that offers both durability and adaptability. This choice helps you get the most from your investment and keeps your production line running smoothly.

When picking a Fiber Laser Head, check every feature. Each feature helps you do better work and save time. It also helps your machines last longer. The table below shows how these features help:

Feature | Contribution to Performance, Efficiency, and Reliability |

High Precision | Accurate cutting for top-quality work |

Versatility in Cutting | Handles many materials for more jobs |

High Cutting Speeds | Finishes tasks faster |

Non-Contact Processing | Protects your parts and tools |

Narrow Heat-Affected Zone | Keeps materials strong and clean |

Automatic Functionalities | Makes your work easier and smoother |

Make a checklist before you choose your equipment. WSX is a good example of quality and support:

Criteria | Description |

Core Requirements Checklist | Make sure the head fits your material, speed, and space needs |

Budget Planning | Think about future costs, not just what you pay now |

Core Components | Choose trusted brands like WSX for good performance |

Tip: Follow these steps to help you pick the right laser head. This will help your factory work well and stay strong.