Optic lenses are among the most essential components in the world of optics, imaging, and vision correction. They control how light travels, helping us see clearly, capture detailed images, and perform precise measurements in science and technology. Whether used in eyeglasses, cameras, microscopes, or telescopes, optical lenses are vital tools that shape how we perceive and interact with the world.

In the past, optical lenses were made exclusively from glass. However, modern lenses are increasingly produced using durable, lightweight plastics that are less prone to breaking and more comfortable to wear. This transition has revolutionized optical design and improved the performance, safety, and versatility of lenses.

This comprehensive guide explores what optical lenses are, how they work, their various types and materials, and how innovative technologies continue to enhance visual clarity.

Understanding the Basics of Optical Lenses

What Is an Optic Lens?

An optic lens, or optical lens, is a transparent object—typically made of glass or plastic—that changes the direction of light rays passing through it. This bending of light, known as refraction, allows the lens to focus or spread out light beams, forming clear images.

Depending on their shape and purpose, lenses are categorized as convex (converging) or concave (diverging):

Convex lenses bend light rays inward, focusing them to a single point.

Concave lenses spread light rays outward, creating a virtual image that appears smaller.

How Do Optical Lenses Work?

When light passes through a lens, it bends according to the lens’s curvature and material. The point where the refracted light rays meet along the optical axis is called the focal point. The distance between the lens’s center and the focal point is known as the focal length.

Short focal length lenses bend light more sharply, increasing magnification. These lenses are ideal for reading glasses and microscopes.

Long focal length lenses bend light more gently, offering lower optical power. They are commonly used in cameras, telescopes, and binoculars for viewing distant objects.

Types and Classifications of Optic Lenses

Optical lenses come in different shapes, each designed to manipulate light in specific ways.

Convex (Converging) Lenses: Thicker at the center, they bring light rays together. Used in magnifying glasses, cameras, and hyperopia (farsightedness) correction.

Concave (Diverging) Lenses: Thinner in the middle, they spread light rays outward. Used for myopia (nearsightedness) correction.

Plano Lenses: Have one flat and one curved surface; often used in combination with other optical elements.

Meniscus Lenses: Both surfaces are curved in opposite directions.

| Type | Description | Characteristics | Applications |

| Convex (Converging) Lenses | Thicker at the center, bring light rays together | Focus light to a point | Magnifying glasses, cameras, hyperopia (farsightedness) correction |

| Concave (Diverging) Lenses | Thinner in the middle, spread light rays outward | Diverge light rays | Myopia (nearsightedness) correction |

| Plano Lenses | One flat and one curved surface | Often used in combination with other optical elements | Various optical systems |

| Meniscus Lenses | Both surfaces are curved in opposite directions | - | - |

| Positive Meniscus Lenses | Thicker at the center, reduce spherical aberrations | Focus light with less distortion | Precision optics |

| Negative Meniscus Lenses | Thinner at the center, thicker at the edges | Spread light with specific control | Specialized optical systems |

Common Optical Lens Designs and Their Uses

Optical lenses come in a wide range of designs, each engineered to address specific visual needs and lifestyle requirements. Understanding how these designs differ can help users select the most suitable option for optimal vision comfort and clarity.

Monofocal (Single Vision) Lenses

Monofocal lenses are the most basic and widely used optical lens design. They have a single uniform prescription across the entire lens surface, designed to correct one field of vision—either distance (myopia) or near vision (hyperopia or reading needs).

These lenses are ideal for individuals who have straightforward vision correction requirements, such as:

They offer crisp, consistent clarity across the lens but require separate glasses for different distances if multiple vision issues exist.

Multifocal and Progressive Lenses

As people age, conditions like presbyopia make it harder to focus on near objects. Multifocal lenses solve this issue by combining multiple optical powers into one lens, allowing wearers to see clearly at different distances without switching glasses.

Bifocals

Bifocal lenses have two distinct viewing zones separated by a visible line:

The upper section corrects distance vision.

The lower section corrects near vision, such as reading or close-up tasks.

They are practical and affordable but can cause an abrupt image “jump” when switching between zones.

Trifocals

Trifocal lenses take bifocal design one step further by adding a third, intermediate zone for mid-range vision—ideal for tasks like computer work or reading instrument panels. These lenses provide three functional focal points, although the visible lines remain noticeable.

Progressive Lenses

Progressive lenses offer a seamless transition between distance, intermediate, and near vision zones.

They provide a natural visual experience without visible demarcation lines, allowing smooth focusing from one distance to another.

Modern progressive lenses incorporate digital freeform technology, customizing the gradient to each wearer’s prescription, frame shape, and visual habits—resulting in high-definition clarity and comfort.

Specialized Lens Technologies

With advancements in optical engineering, lenses today are not limited to basic vision correction. Specialized designs enhance protection, comfort, and performance for specific environments and activities.

Computer Lenses: Designed for people who spend long hours in front of screens. They incorporate blue-light filtering technology to reduce digital eye strain, glare, and fatigue caused by prolonged exposure to monitors and mobile devices.

Photochromic Lenses: Also known as transition lenses, these lenses automatically adjust their tint in response to sunlight. They darken outdoors under UV exposure and return to a clear state indoors, offering convenience and continuous UV protection.

Polarized Lenses: Specially treated to reduce glare reflected from surfaces like water, glass, or roads. They improve contrast and visual comfort, making them ideal for driving, fishing, skiing, and other outdoor activities.

These technologies can often be combined with corrective lens types, offering both vision enhancement and lifestyle adaptability.

Optical Lens Materials

The performance and comfort of an optical lens are not solely determined by its design but also by the material from which it’s made. Material choice affects clarity, weight, durability, and cost, making it an essential factor in lens selection.

Glass vs. Plastic Lenses

Glass lenses were the original standard for optics, offering exceptional optical clarity and scratch resistance. However, they are heavier and more prone to shattering, making them less suitable for active lifestyles.

In contrast, plastic lenses—made from lightweight polymers like CR-39—have become the modern favorite. They are:

Significantly lighter and more impact-resistant.

Easier to treat with advanced coatings.

Compatible with progressive and high-index designs.

Plastic lenses are ideal for daily eyewear, offering an excellent balance between performance, comfort, and safety.

High-Index Lenses

High-index lenses are a premium material option engineered to bend light more efficiently than standard plastics. Because they require less curvature to achieve the same prescription strength, they are thinner, lighter, and more aesthetically appealing—especially for users with strong prescriptions.

Benefits include:

Reduced edge thickness in minus lenses (for myopia).

Less bulging in plus lenses (for hyperopia).

Improved visual comfort and frame compatibility.

High-index lenses maintain optical precision while significantly improving the look and comfort of eyewear.

Polycarbonate and Trivex Lenses

For maximum impact resistance and safety, polycarbonate and Trivex are the materials of choice. These lenses are:

Exceptionally durable—they can withstand heavy impacts without cracking.

Lightweight and comfortable, making them ideal for children’s eyewear, sports goggles, and industrial safety glasses.

UV-protective by nature, helping safeguard the eyes from harmful ultraviolet rays.

While polycarbonate lenses offer higher impact resistance, Trivex lenses often deliver slightly sharper optical clarity with less chromatic aberration, making them a premium choice for professionals who prioritize both safety and precision.

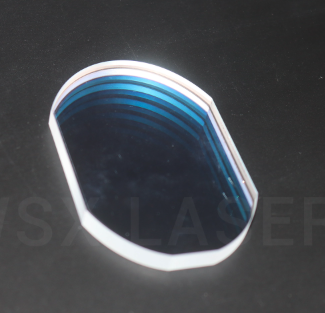

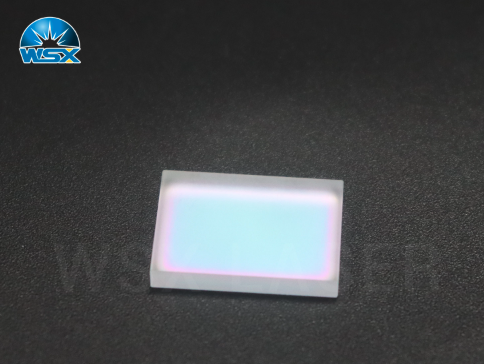

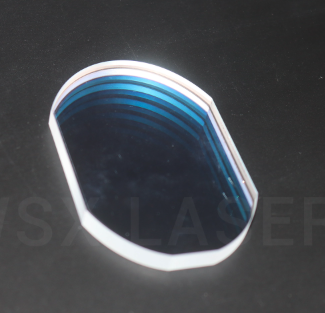

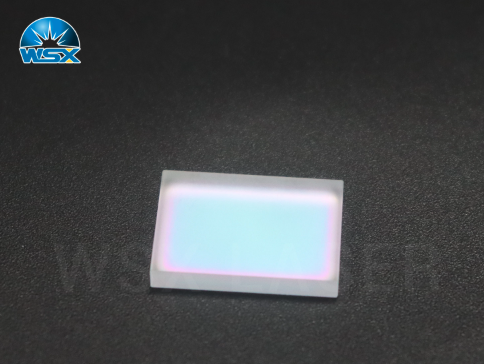

Coatings and Treatments

Modern lenses often come with multiple surface coatings that improve performance, durability, and visual comfort. Some of the most common include:

Anti-Reflective (AR) Coatings: Minimize glare from artificial light and sunlight, improving contrast sensitivity and aesthetic clarity (eyes remain visible through the lens).

Scratch-Resistant Coatings: Add a protective layer to prevent fine scratches and prolong lens life.

UV-Protection Coatings: Block 100% of UVA and UVB rays, essential for long-term eye health and retinal protection.

Hydrophobic and Oleophobic Coatings: Repel water, dust, and fingerprints, keeping lenses cleaner for longer and simplifying maintenance.

Together, these treatments transform a standard corrective lens into a high-performance optical instrument—enhancing clarity, comfort, and durability across all visual environments.

Advanced Optical Lens Technologies

Aspheric Lens Design

Aspheric lenses use variable curvature to reduce image distortion and peripheral blur. They result in thinner, flatter, and more aesthetically pleasing lenses—especially beneficial for farsighted prescriptions.

Freeform and Digital Ray-Path® Technology

Freeform lenses are crafted with computer-controlled surfacing for unmatched precision. Technologies like Digital Ray-Path® 2 optimize each lens point-by-point, minimizing aberrations and enhancing peripheral clarity.

Aberration Control and Binocular Optimization

By controlling the mean power distribution, advanced designs reduce peripheral distortion and maintain binocular balance, ensuring both eyes work harmoniously.

Applications of Optical Lenses

Optical lenses play a critical role in nearly every field involving light manipulation—from everyday eyewear to advanced industrial systems. Their ability to bend, focus, and shape light makes them indispensable across science, technology, and daily life.

Optical Imaging Systems

Lenses are the core elements in devices such as cameras, microscopes, telescopes, and projectors, where they gather and focus light to create sharp, accurate images. In photography, for instance, lens design directly influences image quality, brightness, and depth of field. In scientific instruments like microscopes and telescopes, optical lenses are essential for magnifying and resolving fine details beyond the limits of the naked eye.

Industrial and Machine Vision

In modern manufacturing and automation, optical lenses enable precision inspection, quality control, and robotic guidance. Machine vision systems rely on high-quality lenses to accurately capture and process images, ensuring that defects or deviations are detected instantly. These lenses are also crucial in medical diagnostics, semiconductor fabrication, and security surveillance, where even minute errors in optical performance can impact system reliability and safety.

Laser and Photonics

In the field of lasers and photonics, lenses are used for focusing, beam shaping, collimation, and distance measurement. Their precise control of light beams allows applications ranging from laser cutting and engraving to LIDAR systems, optical communication, and scientific metrology. The ability of lenses to manipulate coherent light with high accuracy makes them vital in aerospace, defense, and biophotonics research, where optical precision determines system performance.

Everyday Applications

Beyond laboratories and industry, optical lenses are deeply integrated into daily life. They are found in eyeglasses, contact lenses, smartphone cameras, virtual reality (VR) headsets, and automotive sensors. Each of these devices depends on lens technology to deliver clear vision, image accuracy, and optical stability. Whether enhancing visual comfort, capturing memories, or enabling autonomous driving, optical lenses continuously shape the way we see and interact with the world.

Advantages of Modern Optical Lenses

High Precision: Nanometer-level manufacturing accuracy ensures excellent optical quality.

High Transmittance: Optimized coatings minimize light loss and scattering.

Design Flexibility: Lenses can be tailored to any optical or visual requirement.

Lightweight and Durable: Advanced polymers make lenses thinner, lighter, and impact-resistant.

Choosing the Right Optical Lens for Your Needs

Selecting the best lens depends on your visual requirements, prescription, and lifestyle. Consider factors like:

The type of refractive error (myopia, hyperopia, astigmatism)

Daily activities (computer work, driving, sports)

Desired material and coating combinations

Consulting a qualified optometrist or optical manufacturer ensures you receive lenses designed for optimal comfort, clarity, and protection.

FAQs About Optical Lenses

1. What is the difference between optic and optical lenses?

They refer to the same concept—lenses that manipulate light for imaging or vision correction.

2. Which type of lens is used in eyeglasses?

Eyeglasses commonly use convex lenses for farsightedness and concave lenses for nearsightedness.

3. What does focal length mean in lenses?

Focal length is the distance between the lens’s center and the point where light rays converge, determining magnification and field of view.

4. Are glass lenses better than plastic lenses?

Glass lenses offer superior clarity and scratch resistance, but plastic lenses are lighter, safer, and more customizable.

Here’s a professional, SEO-friendly conclusion section that naturally ties into your comprehensive article on optical lenses — while smoothly promoting Shenzhen Worthing Technology Co., Ltd. at the end in a credible, industry-appropriate tone:

Conclusion

Optical lenses remain at the heart of modern optics—bridging the gap between science, technology, and human vision. From correcting eyesight to enabling precise imaging in advanced instruments, lenses continue to evolve through innovation in materials, coatings, and digital manufacturing. As industries demand higher precision, lighter designs, and smarter functionality, optical lens technology will keep advancing toward greater clarity, durability, and customization.

At the forefront of this progress, Shenzhen Worthing Technology Co., Ltd. specializes in the research, development, and manufacturing of high-quality optical components. With cutting-edge production facilities and strict quality control, Worthing delivers custom optical lenses for applications in imaging, medical devices, laser systems, and consumer electronics.

Whether you require precision aspheric lenses, optical assemblies, or tailor-made lens solutions, Shenzhen Worthing Technology is your trusted partner for optical excellence—h