Optics lenses for industrial laser systems are growing fast. There is always something new being made. Makers use better materials and coatings to make lenses last longer. These also help the lenses work better. WSX makes high-transmittance lenses. These lenses help control the laser beam very well. They are used in aerospace, healthcare, and manufacturing. These trends make industry standards go up. They also change how people pick parts for safe and good laser work.

Key Takeaways

The optics lenses market will grow by 3.7% each year from 2025 to 2035. This is because more people want them in manufacturing and healthcare.

Advanced materials and coatings make lenses work better. They also make lenses stronger and more useful for laser jobs.

AI helps make lenses by checking quality and helping with design. This means optical products are getting better.

Sustainability is very important now. Companies use eco-friendly materials and better ways to help the environment.

To do well, companies must make their products stand out. They should give more value to customers and use new technology and rules.

Optics Lenses Market Trends

Global Growth

The optics lenses market is getting bigger every year. Experts think it will grow by 3.7% each year from 2025 to 2035. This means more people want these lenses for factories, hospitals, and electronics. Companies spend money on new ideas to make lenses work better and last longer. More businesses use advanced optics lenses to meet higher rules. Top brands like WSX make strong and accurate lenses. These new trends make companies try harder to make better products.

Regional Hotspots

Some places use more optics lenses than others.

Asia-Pacific is growing the fastest. More factories, new tech, and more money help this area use better optics.

North America and Europe are also busy. They work on new ideas and special uses for these lenses.

Region | Key Factors Driving Adoption |

Asia-Pacific | Big electronics factories and help from the government |

North America | New ideas in planes, defense, and medical lasers |

Europe | Focus on new research, especially in Germany and France |

Emerging Economies | Slowly using lasers in factories and hospitals |

These differences in each place change the world market. They also affect how companies make and sell their lenses.

Market Drivers

Many things make people want better optics lenses for lasers.

More people want good cameras, sensors, and AR devices. This makes companies need better lenses.

Faster internet and more data centers need lenses that can send light quickly.

Hospitals need better lenses for imaging and tests. This makes companies work on more exact and strong lenses.

People care about saving energy and making things in better ways. This makes companies use better materials and methods.

Top lenses, like those from WSX, set new rules for the market. These lenses use great materials, special coatings, and unique designs. The industry now cares about high quality, new tech, and custom features. Companies make lenses that are clearer, last longer, and work better.

Trend | Description |

Premiumization | People in cities want better and stronger materials. |

Technological Advancements | New lens designs, like anti-reflection, are now very important. |

Specialized Features | More people want custom lenses for special needs. |

The optics industry keeps changing as these trends shape what companies make and what buyers want.

Optics Lenses Innovations

Advanced Materials

Makers use new materials to make lenses stronger. These materials help lenses work better and last longer. Special glass helps make images look sharper. It stops light from spreading too much. Tough glass can handle rough places. This makes lenses work well in hard jobs. These changes help laser systems in factories, hospitals, and labs.

Material Type | Performance Benefits |

Advanced Glass Compositions | Minimal dispersion, high refractive indices for sharper imaging |

Ultra-Durable Glass | Withstands extreme conditions, ensuring reliability in demanding environments |

New materials make lenses last longer and work better. Precision optics are important for laser cutting and welding. Good optical parts help focus the laser beam. This is needed for good laser work.

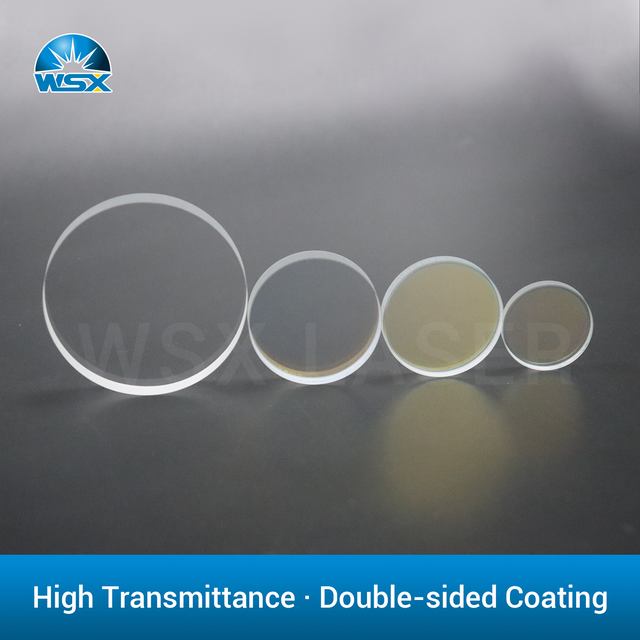

Coating Technologies

Coating technology has improved a lot. Dielectric HR coatings now reflect over 99.5% of light. These coatings help make images clearer and signals stronger. They also work well with strong lasers and in tough places.

New ways to add coatings, like PECVD, help put on anti-reflective and water-repelling layers at once. New materials like silicon dioxide and titanium dioxide make coatings clear and absorb less light. Hybrid coatings mix different layers for special uses.

Diamond over-coat (DOC) makes lenses last longer. This coating lets people clean lenses many times. It does not get damaged easily. It mixes diamond-like carbon with other coatings. This saves money and keeps lenses working well.

AI Integration

Artificial intelligence is changing how lenses are made. AI machine vision checks lens parts for quality. This helps make sure lenses are good and safe. AI also helps fix problems before they get worse.

AI tools help design lenses faster and better. They control how light moves through lenses. Machine learning finds small mistakes that can hurt image quality. This helps makers build better lenses.

Modern vision systems use 2D cameras to find problems fast.

AI gives real-time checks and helps automate work.

Machine learning makes designs better for each job.

Smart robots measure lenses in 3D for more safety and accuracy.

Precision Engineering

Precision engineering helps make new and better lenses. Knowing how the whole system works saves money and boosts performance. Special ways of making lenses, like cutting and polishing, make parts work better.

Automation and real-time checks help make lenses the right shape. Laser tools cut and engrave with great detail. Computers help shape lenses with very high accuracy. Polishing makes lens surfaces very smooth.

Lens Model | Technology Used | Benefits |

SY-BS-60406 | Advanced Spectral Quartz | Enhanced optical performance and durability |

SY-BS-30203 | Advanced Spectral Quartz | Suitable for a wide range of laser applications |

WSX’s SY-BS-60406 and SY-BS-30203 lenses use special quartz. These models set new rules for how well lenses work and last. Their high-transmittance and strong coatings fit modern laser needs.

The newest trends in optics lenses show that better materials, coatings, AI, and engineering are moving the market forward. These changes help everyone get better results in all kinds of laser work.

Industry Applications

Manufacturing

Factories use optics lenses to help with laser cutting and welding. These lenses make machines work faster and more accurately. High-transmittance lenses focus the laser for clean cuts and strong welds. WSX makes cutting heads and welding robots for many factories. Their 15-50KW cutting heads work well for tough jobs. The 6KW ring-shaped welding head helps with hard welding tasks. Scanning mirror welding heads also help with tricky jobs. These products make factory work easier and more reliable.

Automotive

Car companies use optics lenses in driver help, night vision, and LIDAR. These lenses help cars see better and measure how far things are. Special coatings and shapes make images clearer and safer. The table below shows which lenses fit each job:

Application | Optical Components Used |

Driver Assistance Systems | Aspheric lenses for better pictures |

Night Driving Systems | Spherical and aspheric lenses with coatings |

LIDAR Systems | Optical parts for 3D pictures and measuring |

WSX makes products for cars, like small cutting heads and welding tools for car parts.

Defense

Defense teams use optics lenses for aiming, finding, and seeing things. These lenses help with aiming and seeing in the dark. New lens designs make devices smaller and lighter. The table below shows important uses:

Application | Description |

Laser Targeting | Devices that help aim by showing a bright spot, used by police and military. |

LiDAR Detection | Airborne imaging tools that use different parts for defense, focusing on size and cost. |

Infrared Imaging | Helps see and find things in the dark, making defense work better. |

WSX gives defense teams strong and flexible laser parts.

Medical

Doctors use optics lenses for surgery, imaging, and tests. New ideas include adaptive optics, GRIN lenses, and fiber optics. These help doctors do careful work and see inside the body. Femtosecond laser eye surgery uses beam shapers for exact cuts. Wavefront-guided LASIK uses adaptive optics to fix vision. High-resolution endoscopy uses fiber optics for clear pictures.

Optics lenses make images better so doctors can see more.

They help doctors do less invasive work with good aim.

Lenses fix vision problems to keep things clear during surgery.

WSX gives strong lenses for medical lasers, helping doctors treat patients safely and accurately.

Lenses Challenges and Opportunities

Cost Factors

Making advanced lenses costs more money now. Small companies find it hard to keep up. Strict rules for quality make things tougher. New tariffs on imported lenses raise prices for buyers and stores. Special raw materials, like rare-earth elements, are hard to get. Companies must give good optics but keep prices fair. Many invest in new tech and green materials to save money over time.

Supply Chain

Problems in the supply chain change how easy it is to get lenses and how much they cost.

High costs and supply chain issues make it hard for small users to buy lenses.

Strict quality checks add to the price, so some worry about cost.

Tariffs and world problems mess up prices and how materials move.

The industry needs special raw materials, so shortages can happen.

New tech makes making lenses cost more, so some buyers cannot afford them.

Makers try new ideas and use green materials to keep supply chains strong. They also work with partners to get steady supplies and good delivery.

Customer Demands

What customers want helps change how laser optics are made. Many people now ask for lenses that work with many kinds of lasers. They want products that last long and work well. The table below shows what customers look for:

Customer Demand | Description |

High-performance optics | Works well with strong power and energy |

Compatibility | Fits with many types of lasers |

High-damage-threshold coatings | Stays clear even with strong laser use |

Rugged optical surfaces | Tough for high-energy jobs |

Advanced metrology | Good for top laser systems |

WSX protective lenses meet these needs. They are tough, clear, and easy to clean. Their design fits well and works better, so machines stop less and work more.

Sustainability

Being green is very important in making optics now. Companies use materials like PMMA and other plant-based choices. They make things in ways that use less energy and lower pollution. Water-saving steps, like recycling, help cut waste. Many companies use less plastic and make better packages. They team up with suppliers and buyers to make new green tech. These actions help the planet and make the industry better.

Future Trends and Strategy

2025 Outlook

The optics lenses market will change a lot by 2025. New technology will affect how companies make and use lenses. Experts think AR and VR optics will get better. Light field displays and holographic lenses will be used more. These features make lenses smaller and clearer. This helps in factories and other jobs. Silicon photonics and quantum optics will be used more often. These help make optical parts cheaper and faster.

The table below shows the main trends and what they mean:

Trend Description | Implication |

Advancements in AR/VR optics, including light field displays and holographic lenses | Makes optics smaller and clearer, which is important for factories. |

Growth of silicon photonics and quantum optics | Helps make cheaper optical parts for laser systems. |

Development of coherent pluggable optics (e.g., 400G ZR+) | Needed for bigger data centers, which use lasers. |

Precision optics in automotive and defense sectors | These areas need better optics for laser jobs. |

Resurgence of managed optical fiber networks (MOFNs) | Gives cloud companies better ways to use optics. |

Asia-Pacific leading in AR/VR adoption | More people want optics for games and training, so the market grows. |

Companies that follow these trends will do well. They will make better products and meet new needs in many jobs.

Strategic Actions

Industry leaders need to act now to stay ahead. They should focus on what makes their products different. Special features help companies stand out. Making customers happy is also important. When customers see more value, they stay with the company.

The table below lists key actions for success:

Strategic Action | Description |

Differentiate products and services | Make products special so people notice them. |

Enhance customer value propositions | Give customers more value so they stay loyal. |

Create switching costs and barriers | Make it hard for customers to leave for another company. |

Pursue consolidation | Join with or buy other companies to get stronger. |

Innovate or diversify | Make new products or try new markets to get more customers. |

Adapt to regulatory shifts | Follow new rules to avoid problems and keep selling. |

Embrace technological advancements | Use new technology to make products better and work faster. |

Premium optics lenses, like WSX’s, help companies reach these goals. They use strong materials and coatings for better performance. By using these strategies, companies can build strong brands and get ready for the future.

Being open to new ideas and changes will help companies win in the changing optics market.

The optics lenses industry for industrial laser systems is changing fast. New materials, better coatings, and AI help make lenses work better. These updates help factories, car makers, defense teams, and doctors do their jobs. People can do well by using premium optics lenses like WSX. These lenses have new technology, follow rules, and use smart market plans.

Factor | Description |

Technological Advancements | New optical technology makes lenses work better and last longer. |

Regulatory Compliance | Following strict rules helps people trust the products. |

Market Strategies | Selling in more places helps more people get good optics. |

In the future, people who try new ideas and work together will lead in industrial laser optics.