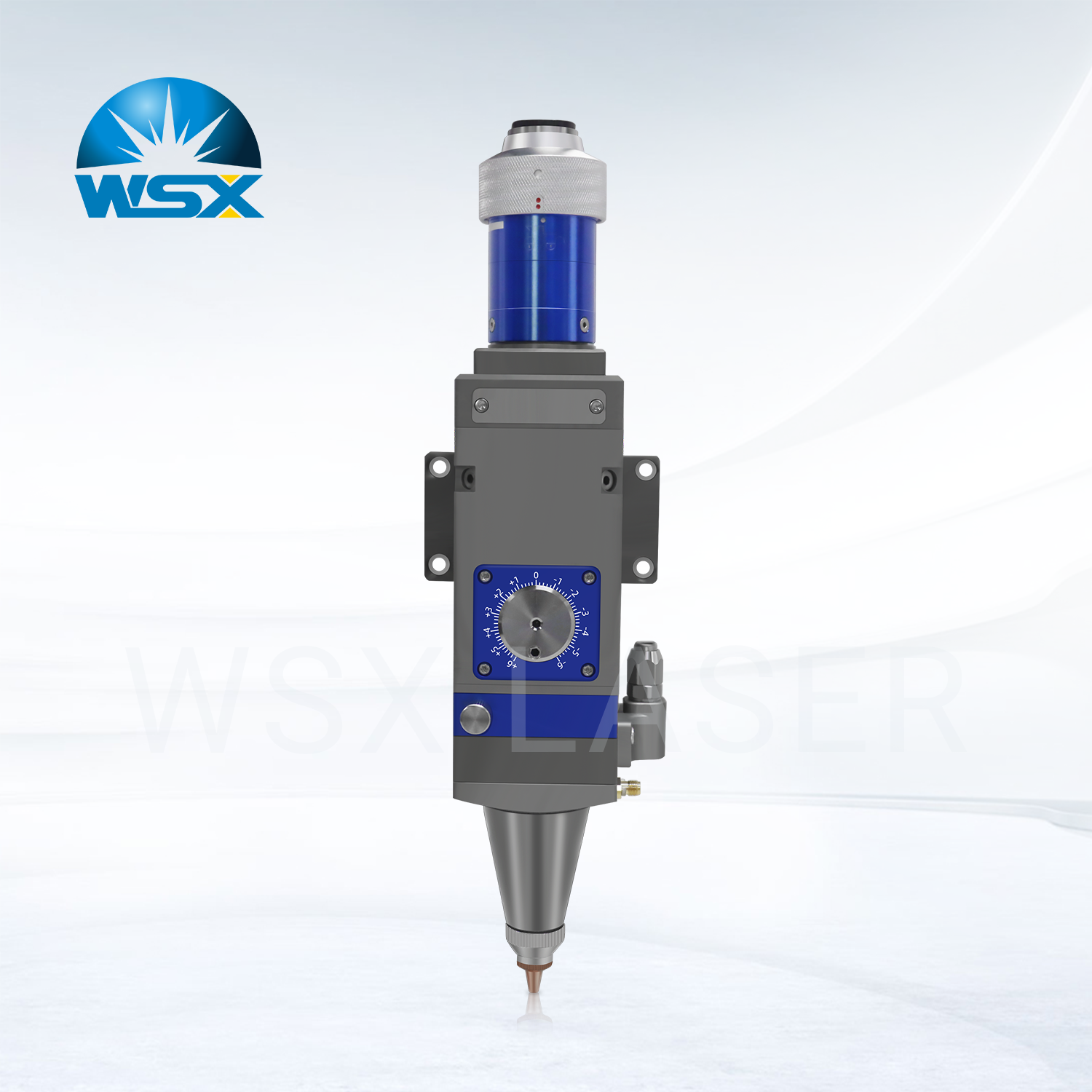

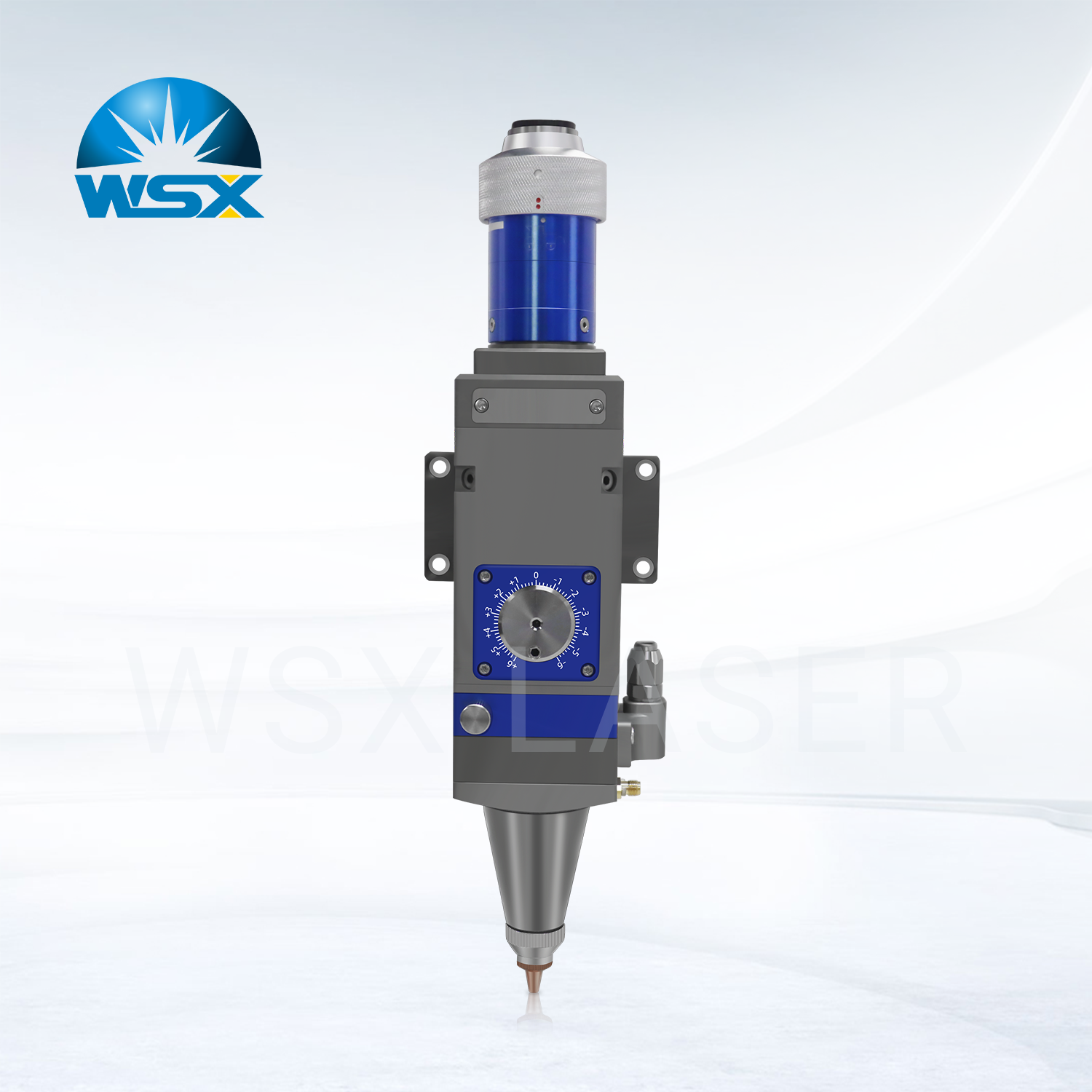

Understanding the SW30 3D Laser Cutting Head

The SW30 Three-Dimensional Laser Cutting Head is a high-performance tool designed exclusively for 3KW three-dimensional pipe cutting applications. It combines lightweight, compact design with powerful functionality, making it ideal for integration with robotic arms and automated production lines. Unlike standard cutting heads that struggle with complex 3D shapes, this 3D laser cutting head features unique focus adjustment mechanisms and advanced optical engineering to deliver precise, efficient cuts on pipes and complex workpieces. Its robust construction and protective features ensure stability and durability, even in demanding industrial environments. The SW30 redefines 3D pipe cutting by offering versatility, precision, and ease of use, supporting businesses in tackling complex cutting tasks with confidence.

Typical Uses of the SW30 Cutting Head

3D Pipe and Tube Fabrication

Manufacturers of pipes and tubes rely on the SW30 laser cutting head for precision 3D cutting. It handles various pipe shapes and sizes, from standard round tubes to complex profiles, enabling the production of custom pipe components for industries such as construction, automotive, and HVAC. Its ability to cut intricate patterns and joints reduces post-processing work, improving production efficiency.

Robotic Automation Integration

In automated manufacturing facilities, the SW30 3D laser cutting head is seamlessly integrated with robotic arms. Its lightweight design allows for easy maneuvering, supporting complex 3D cutting tasks in automated production lines. Industries using robotic automation for mass production leverage its precision and speed to enhance throughput and ensure consistent cut quality across high-volume runs.

Custom 3D Cutting Projects

Custom fabrication shops and specialty manufacturers use the SW30 cutting head for complex 3D cutting projects. It adapts to diverse workpiece shapes and materials, supporting the creation of custom components, artistic installations, and specialized equipment. Its flexible focus adjustment and versatile design make it a valuable tool for projects that require creativity and precision.

Parameter | Value |

Laser Wavelength | 1070±30nm |

Collimation Focal Length | F100 |

Focusing Focal Length | F125/F150/F190 |

Collimation Protective Mirror | D25.4*4 |

Focusing Protective Mirror | D25.4*4 |

Centering Adjustment Range | ±1.5mm |

Nozzle Type | Single-layer |

Applicable Power | ≤3KW |

Weight | 2.5kg |

Nozzle Aperture | 1.2/1.5/1.8/2.0/2.5/3.0 |

Design Specifications of the SW30 Cutting Head

Precision Adjustment and Compatibility

The SW30 3D laser cutting head features two-point centering and curve-driven focus adjustment, allowing operators to set focus quickly and accurately. It is equipped with QBH and OCS fiber interfaces, ensuring compatibility with a wide range of laser sources. This high adaptability allows integration into existing setups without costly equipment overhauls.

Protective and Maintenance-Friendly Design

The E’25 drawer-type protective lens design enables quick and easy lens replacement, minimizing machine downtime. The 922 high-level sealing feature protects internal optical components from dust and debris, extending lens lifespan and reducing replacement costs. The lightweight, compact structure ensures easy mounting on robotic arms and maneuverability in tight spaces.

FAQ About the SW30 3D Laser Cutting Head

Is the SW30 suitable for high-volume 3D pipe cutting?

Yes, the SW30 cutting head is designed for high-volume industrial use. Its efficient focus adjustment, durable construction, and compatibility with automated systems make it ideal for continuous 3D pipe cutting in mass production environments.

How easy is it to replace the protective lens on the SW30?

The drawer-type protective lens design allows for lens replacement in minutes, with no specialized tools required. This quick process minimizes downtime and ensures continuous production, even when lens maintenance is needed.

Can the SW30 be used with different laser sources?

Absolutely. The cutting head features QBH and OCS fiber interfaces, enabling easy integration with most standard 3KW laser sources. Its high compatibility eliminates the need for custom adapters or modifications.

What makes the SW30 ideal for robotic arm integration?

The SW30 3D laser cutting head is lightweight and compact, making it easy to mount and maneuver on robotic arms. Its precise focus adjustment and stable performance ensure accurate cuts even during fast, complex robotic movements.