If you operate a laser cutter or engraver, you know every small component matters, and the ceramic ring is one of the most critical. It shields lenses from debris, stabilizes the laser beam, and ensures every cut remains precise. When it cracks, even tiny fractures can cause misaligned beams, rough edges, or uneven kerfs. Not only does this reduce cutting quality, it can also increase downtime and repair costs. Understanding why ceramic rings crack helps prevent damage, improves maintenance practices, and keeps your machine running efficiently for years.

Understanding Ceramic Rings in Laser Equipment

What Is a Ceramic Ring?

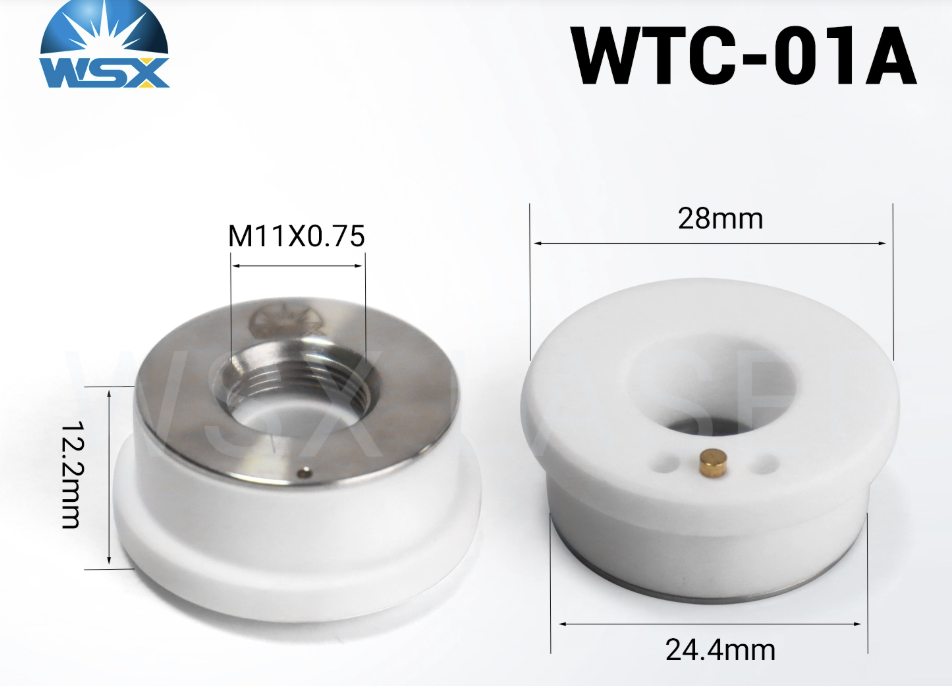

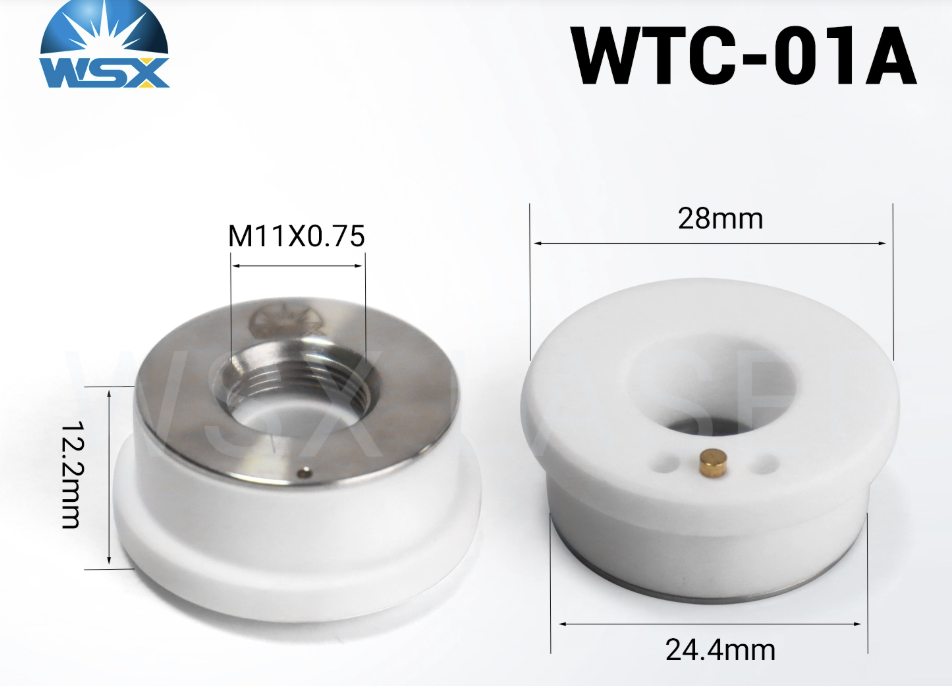

A ceramic ring is a small, high-strength component located around the nozzle or lens of a laser head. It acts as a protective barrier, keeping debris, sparks, and intense heat away from sensitive parts. Ceramic rings are usually made from high-purity materials such as alumina, zirconia, silicon carbide, or silicon nitride. Each material has unique properties, including thermal conductivity, mechanical strength, and resistance to wear or chemical corrosion. Choosing the right type depends on your laser’s power, the materials you cut, and the frequency of use. These rings may seem simple, but they directly influence beam stability, focal length consistency, and overall cutting quality.

How Ceramic Rings Work

Ceramic rings serve both protective and performance-enhancing roles. They absorb heat, reduce thermal expansion around the lens, and prevent contamination from sparks or metal shavings. They also help maintain a consistent laser beam path, which is essential for clean, accurate cuts. Without them, lenses can become scratched or coated with debris, focusing becomes inconsistent, and the cutting process can produce rough edges or uneven kerfs. Essentially, a healthy ceramic ring ensures the machine operates smoothly and reliably.

Common Signs of Ceramic Ring Cracking

You don’t always notice ceramic ring damage immediately. Watch for these warning signs:

Visible chips, cracks, or hairline fractures: Even tiny cracks can grow under heat and stress.

Uneven or rough cuts: Edges may appear jagged, kerfs inconsistent, or sparks may scatter differently than usual.

Frequent recalibration: The laser may require constant adjustment to maintain focus.

Shorter ring lifespan: The component may wear out faster than expected due to stress accumulation.

Recognizing these issues early can prevent further damage to the laser head or other parts.

| Sign | Description |

| Visible chips, cracks, or hairline fractures | Even tiny cracks can grow under heat and stress. |

| Uneven or rough cuts | Edges may appear jagged, kerfs inconsistent, or sparks may scatter differently than usual. |

| Frequent recalibration | The laser may require constant adjustment to maintain focus. |

| Shorter ring lifespan | The component may wear out faster than expected due to stress accumulation. |

Primary Causes of Ceramic Ring Cracking

Thermal Shock

Laser cutting generates extremely high temperatures at the cutting point. When the material or ring cools too quickly, the ceramic experiences thermal shock. Even strong materials like zirconia or silicon nitride can develop microfractures under repeated cycles. This is especially common during high-power metal cutting or when performing back-to-back jobs without giving the machine a cooldown period.

Mechanical Stress

Incorrect installation, overtightening screws, or misaligned rings can put mechanical stress on ceramics. Vibration from machine operation or accidental bumps can further weaken the ring. Over time, these small forces accumulate, creating cracks that eventually compromise performance.

Material Defects

Ceramics are brittle by nature. Low-quality rings, impurities, or poor manufacturing processes reduce their toughness. Alumina, for instance, is more prone to cracking than zirconia under high stress. Manufacturing defects like tiny air pockets or uneven density can create weak points, making the ring vulnerable during normal operation.

Contamination

Debris, metal particles, or carbon deposits that accumulate on the ring can cause uneven stress distribution. This pressure can initiate microcracks, which grow gradually and may eventually split the ring. Frequent inspection and cleaning help reduce this risk.

Incorrect Laser Parameters

High laser power, extreme cutting speeds, or improper focus settings place additional thermal and mechanical strain on ceramic rings. Over time, these conditions accelerate crack formation, especially if the ring material isn’t optimized for high-power or high-speed operations.

Effects of Ceramic Ring Cracking on Laser Equipment

Even minor cracks can have significant consequences:

Reduced cutting accuracy: Misaligned laser beams produce inconsistent kerfs and rough edges.

Damage to other components: Debris or sparks can scratch lenses or wear down nozzles.

Increased operational costs: More frequent replacements, downtime for repairs, and material waste.

| Problem | Effect on Machine |

| Crack in ring | Beam misalignment, rough cuts |

| Debris buildup | Lens contamination, reduced precision |

| Warping from heat | Requires recalibration or replacement |

| Frequent vibration | Accelerates wear, shortens ring lifespan |

Preventing Ceramic Ring Cracking

Proper Installation

Correct installation reduces stress. Align the ring carefully, press by hand first, and tighten screws evenly. Avoid overtightening; excessive force can crack even strong ceramics. Using the correct tools, following the manufacturer’s guidelines, and checking alignment during installation are crucial for longevity.

Optimize Laser Parameters

Using appropriate laser power, speed, and focus helps reduce thermal and mechanical stress. Adjust settings based on material type and thickness. Avoid rapid heating and cooling cycles during intensive operations.

Choose the Right Material

| Material | Best Use | Pros | Cons |

| Alumina | Plastics, general metals | Affordable, good thermal conductivity | Brittle, prone to cracking |

| Zirconia | Glass, delicate metals | Strong, wear-resistant | Expensive |

| Silicon Nitride | High-power metals | Low thermal expansion, stable | High cost |

| Silicon Carbide | Hard metals, alloys | Hard, thermal shock resistant | Brittle under impact |

Regular Cleaning & Maintenance

Debris buildup can accelerate cracking. Clean the ring regularly, inspect for cracks, and replace worn components promptly. Preventive maintenance is cheaper than unexpected downtime.

When to Replace a Cracked Ceramic Ring

Signs You Need a Replacement

You should replace a ceramic ring if you notice visible cracks or chips, even small ones, as they can worsen under repeated heat cycles. Another sign is laser beam misalignment, causing uneven kerfs, jagged edges, or inconsistent cuts. Poor cutting performance, irregular sparks, or unexpected splatter can also indicate the ring is compromised.

Safe Replacement Steps

Always power off the machine and let the laser head cool completely before touching the ring. Remove the old ring carefully, clean debris, then install the new ring ensuring it sits flat and aligned. Tighten screws evenly and avoid over-tightening. Finally, perform a low-power alignment test and a trial cut, recalibrating if necessary to ensure accurate performance.

Innovations Reducing Ceramic Ring Cracking

Advanced Materials: Nanoceramics

Nanoceramic rings are engineered for superior heat resistance, wear resistance, and fracture toughness. They can handle high-power, repetitive laser cutting without cracking. This material improvement significantly extends ring lifespan and maintains cutting precision under extreme conditions.

Sensor Technology and Improved Nozzles

Sensor-equipped rings detect microcracks in real time, alerting operators before full failure occurs. Optimized nozzle designs distribute heat evenly and reduce vibrations, minimizing stress on the ring. Together, these innovations prevent damage, reduce maintenance costs, and improve overall machine efficiency.

FAQ

What causes ceramic rings in laser cutters to crack?

Ceramic rings crack due to thermal shock, mechanical stress, material defects, contamination, or incorrect laser settings.

How can I tell if a ceramic ring is damaged?

Look for visible chips, hairline fractures, uneven cuts, misaligned beams, or frequent need for recalibration.

How often should I inspect the ceramic ring?

You should inspect it regularly, especially after long cutting sessions, high-power operations, or when switching material types.

Can a cracked ceramic ring damage the laser machine?

Yes, it can misalign the beam, scratch lenses, reduce cutting accuracy, and increase maintenance costs.

How do I prevent ceramic rings from cracking?

Proper installation, selecting the right material, optimizing laser power and speed, avoiding thermal shocks, and regular cleaning help prevent cracking.

Conclusion

Ceramic rings play a crucial role in maintaining laser cutting precision, protecting sensitive components, and ensuring smooth operation. Understanding why they crack, recognizing early warning signs, and following proper maintenance and replacement practices can save time, reduce costs, and improve overall cutting quality. Advances like nanoceramics, sensor-equipped rings, and optimized nozzle designs further enhance durability and performance, helping operators achieve consistent, high-quality results.

For businesses looking for reliable laser components and advanced solutions, Shenzhen Worthing Technology Co., Ltd. offers high-quality ceramic rings and cutting-edge accessories designed to extend machine lifespan and maximize performance. Partnering with a trusted supplier ensures your laser equipment operates efficiently, safely, and at peak precision every day.