Laser cutting head technology is changing how factories work. You get very exact cuts. The process is fast and flexible. This helps you finish hard jobs.

The laser cutting head market is growing quickly. You need things to be accurate and efficient.

By 2025, fiber laser cutting machines will be almost 60% of all machines.

Many industries use advanced laser cutting head solutions like WSX for better results.

Advancement | Description |

Increased Precision | Laser cutting head can change focal lengths in tiny steps for perfect cuts. |

Flexibility in Focal Length | You pick the material type and thickness. The laser cutting head changes focus by itself. |

Laser cutting heads make very exact and quick cuts. This changes how many industries work. - WSX models can work with many materials and thicknesses. This helps people get more work done. - Laser cutting helps use less material and saves energy. This makes it cheaper for companies. - Automation features like auto-focus help save time. They also make things more accurate when making products. - Industries like automotive and aerospace finish work faster. They also get better quality parts.

Laser Cutting Head Technology

Core Features

A laser cutting machine shapes and cuts metal very accurately. The most important part is the laser cutting head. This part focuses the laser beam and moves it over the metal. The laser cutting head uses special parts to help you get great results every time.

Here is a table that lists the main parts of a laser cutting head and what each does:

Component | Function |

Focusing Lens | Focuses the laser beam onto the metal, which is important for good cuts. |

Focus Tracking System | Watches and changes the laser cutting head’s position to keep the beam focused. |

Driving Device | Moves the cutting head up and down using a motor and other parts. |

Focusing Lens Seat | Holds the focusing lens so it can focus the laser beam for better cutting. |

Focusing Mirror | Sends the laser beam to the focusing lens. |

Capacitive Sensor | Keeps the nozzle at the right distance from the metal for even cuts. |

Auxiliary Gas Nozzle | Sends extra gas to help cut faster and clear away melted metal. |

Height Sensors | Make sure the nozzle stays at the same distance from the metal for smooth cuts. |

Nozzle | Keeps the right space from the metal, guides gas, and protects the focusing lens. |

All these parts work together when you use the laser cutting machine. The focusing lens and tracking system help you cut metal exactly how you want. The capacitive sensor and height sensors keep the nozzle in the right spot, so your cuts are smooth and even.

The laser cutting head works by aiming a strong laser beam at the metal. The beam heats the metal so fast that it turns into vapor almost right away. This lets you cut the metal without touching it. Saws and shears use force, but the laser cutting machine does not. You get clean cuts with no rough edges.

Tip: The auto-focus feature in WSX heads lets you switch between different metals fast. You spend less time getting ready and more time working.

Advantages Over Traditional Cutting

Laser cutting machines are much better than old cutting tools. Old methods like sawing or shearing use force to cut metal. These ways can leave rough edges and do not work well for tricky shapes. Laser cutting uses a beam of light. You get smooth and detailed cuts every time.

Laser cutting has many good points:

You get very exact cuts with tight spaces. The laser beam can follow hard patterns that old tools cannot do.

You work faster. The laser cutting machine moves quickly and does not need to stop to change tools.

You get a clean finish. The process leaves no rough spots, so you do not need to polish more.

You keep the heat in a small area. The laser heats only a tiny spot, so the rest of the metal stays cool and safe.

Cutting Method | Heat-Affected Zone (HAZ) Size | Reason for HAZ Size |

Laser Cutting | Smallest | Heats only a tiny area |

Plasma Cutting | Intermediate | Uses a wider pulse than a laser beam |

Shearing/Waterjet | None | Does not heat up the metal being cut |

You also save money over time. Laser cutting machines need less fixing than old machines. You do not have to change blades or parts as much. The process makes less waste, so you use more of your metal sheets. One person can run more than one machine at a time, which helps you get more done.

Evidence Type | Details |

Initial Investment Costs | Laser cutting systems cost more at first than old methods. |

Long-term Savings | You save 20-30% over 5 years because you waste less material and pay less for workers. |

Material Waste Reduction | Laser cutting cuts waste by up to 30% with better cutting and planning. |

Labor Cost Efficiency | One person can run many machines, so you get 200-300% more work done. |

Energy Efficiency | New laser systems use 50-70% less energy than CO2 lasers, so you save money. |

You also use less energy. Fiber lasers turn electricity into laser energy at a rate of 50%. CO2 lasers only turn 10% to 20%. Fiber lasers need just 2 to 4 kilowatts for most jobs. CO2 lasers use 7 to 15 kilowatts. You can lower your energy costs by up to 40% with a new laser cutting machine.

Laser cutting services help you finish jobs on time. You can do custom work and big orders with the same machine. You get good results every time. This makes laser cutting a smart choice for any metal shop or factory.

Automotive Manufacturing

Laser Cutting in Automotive Parts

Laser cutting machines are used a lot in car factories. They help shape and cut car parts very accurately. This makes body panels, chassis, and frames fit just right. Laser cutting machines also make dashboards, trim pieces, and exhaust systems. The machines work on both metal and non-metal materials.

Here is a table that shows how laser cutting is used in making cars:

Application | Description |

Body Panels | Makes outside panels fit well and need less fixing. |

Chassis and Frames | Cuts frame parts exactly, which helps keep cars safe. |

Interior Components | Helps make dashboards and trim pieces with great detail. |

Exhaust Systems | Makes tricky exhaust parts that need to be just right. |

Electrical Systems | Makes things like connectors and brackets quickly and accurately. |

Prototyping and R&D | Lets you test new ideas and designs fast. |

Laser cutting machines are used for plastic, airbags, seat belts, leather, fabric, and metal. They trim, seal, and shape these materials for better safety and quality.

Car factories need to make lots of parts fast and change jobs easily. WSX models like SW30 and NC65 help cut hard shapes and 3D surfaces. The SW30 is good for cutting pipes. The NC65 is fast for big jobs. These laser cutting heads make clean cuts and keep the hot area small, so parts stay strong.

Tip: WSX laser cutting heads let you change materials and thicknesses fast. This makes your work easier and quicker.

Benefits for Production

Laser cutting machines give many benefits to car makers. They help you work faster, make better parts, and try new designs. You can do big jobs or special orders.

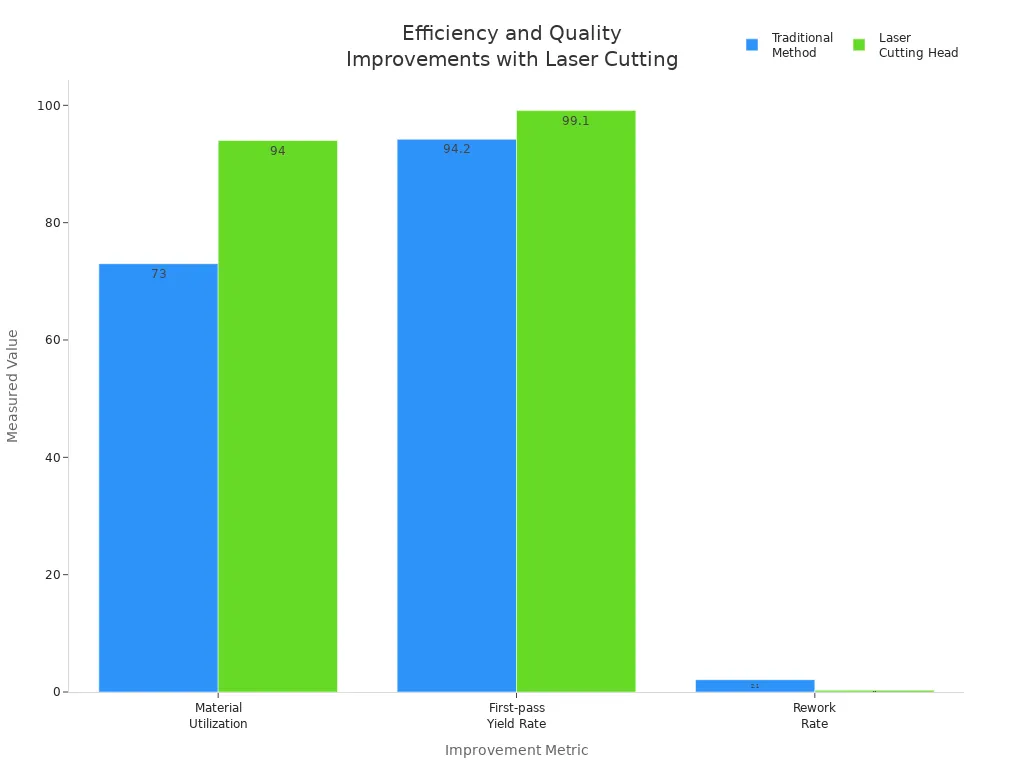

Here is a chart that shows how laser cutting helps car factories do better than old ways:

You use more of your materials, finish jobs faster, and get more good parts the first time. Parts are made to within ±0.001mm. Customer complaints go down by 75%. Rework drops from 2.1% to 0.3%. You save money by wasting less and spending less to run machines.

Laser cutting machines help you make car parts with tight fits. You get smooth edges and fewer mistakes. You can design new shapes for cars. Car factories use laser cutting for speed and good results.

You check your investment by looking at how many parts you make, how well the machine works, and how efficient it is. Fast, powerful laser cutting machines help you reach your goals sooner. You get your money back quickly when you pick the right machine.

Aerospace and Metal Fabrication

Laser Cutting for Aerospace Components

When you use a laser cutting machine in aerospace, you help make important parts. These machines help you meet very strict rules. You need to be very exact with every part. Laser cutting lets you get as close as ±0.1mm. This is very important for safety and how planes work.

Tolerance | Application |

±0.1mm | Aerospace components needing tight tolerances |

Laser cutting helps you make parts that are light but strong. You can trust this process to be exact and dependable. You keep every job within the right limits. In aerospace, you use laser cutting for brackets, engine parts, and panels. The WSX NC152 and NC210 models are good for these hard jobs. These powerful laser cutting heads cut thick metal and tricky shapes easily.

Note: Laser technology is now very important in making airplane parts. It helps you make strong, light pieces with great accuracy. This is needed to meet the tough rules in aerospace.

Metal Fabrication Applications

You find laser cutting machines in many metal shops. These machines help you cut, shape, and finish metal for lots of uses. You get very exact parts, so they fit together well. The WSX NC152 and NC210 models help you work with thick steel, aluminum, and copper.

It is important to keep heat low when you work. Laser cutting makes a small hot area. This keeps your parts strong and stops them from breaking. You save time because you do not need to fix heat damage. Fiber lasers help you finish jobs faster than old tools.

Fiber lasers help stop metal from getting brittle.

You can finish parts faster than with old machines.

Less heat means you spend less time and money fixing parts.

You can work with many kinds of metal in shops. Laser cutting machines let you change jobs fast. You always get smooth edges and clean cuts. This is why laser cutting is a great choice if you want things done right and fast.

Medical and Electronics

Precision in Medical Devices

When you use a laser cutting machine, you help make medical equipment. These machines need to be very exact. Doctors and patients count on tools that must work well. Laser cutting helps you meet these tough rules.

Laser cutting machines use focused lasers to melt or take away tiny bits of material. This lets you make small and detailed parts for medical devices. In the last 30 years, this process has changed a lot. Now, you can make tiny parts for new medical tools with great accuracy.

Ultrafast lasers, like femtosecond lasers, remove material with almost no heat. You get smooth edges and do not hurt the part.

Galvo scan heads and multi-axis scan heads let you control the laser in many ways. You can cut hard shapes without hurting other layers.

You can pick and remove only the material you want. This is important for devices with many layers.

If you use a focus-adjustable head like the NC36, you can do careful jobs easily. You keep the laser focused just right, so every cut is perfect. This helps make sure medical devices are made well and are safe to use.

Electronics Manufacturing

You see laser cutting machines in electronics factories. These machines help you make tiny, strong parts for phones and computers. The NC36 focus-adjustable head gives you control for thin and bendy materials.

Benefit | Description |

Improved cutting accuracy | Autofocus keeps the laser in the best spot for exact cuts. |

Enhanced production efficiency | Automatic focus saves time and helps you make more parts. |

Extended life of optical components | Best focus means less wear, so your machine lasts longer. |

Enhanced adaptability | You can cut many materials and thicknesses without stopping. |

Reduced operational difficulty | Less manual work means fewer mistakes and easier use. |

Laser cutting machines help you make tiny features on semiconductor wafers and flexible circuits. You get clean cuts with no rough spots, so you do not hurt delicate parts. This is important for sensors, screens, and LED parts. You can also cut many types of materials, like metals, plastics, and ceramics.

You get high accuracy for small details.

The laser makes a small hot area, so you do not damage parts.

You can work with many materials, so your process is flexible.

You help the medical and electronics industries by making parts that are small, safe, and reliable.

Construction and Laser Cutting Machines

Custom Fabrication

The construction industry is changing because of new cutting machines. You can make special parts for buildings and bridges. These machines cut metal, wood, and plastic very accurately. You can design hard shapes and get them made just how you want. If you need a special panel or a cool facade, you can make it fast.

Here are some ways these machines help in construction:

You cut exact shapes for beams and supports.

You build models for new building ideas.

You make custom parts that old tools cannot do.

You design fancy panels and cool features.

You shape fittings with perfect sizes.

You make models that match your computer drawings.

You change parts for special jobs.

WSX models like NC30 and NC63 are good for building and metal work. They have strong cutting power and keep your machine safe. The NC30 can cut up to 6kW and works with stainless steel, mild steel, aluminum, and copper. The NC63 cuts thicker metal and uses water cooling to work better.

Model | Laser Power Support | Material Compatibility | Max Cutting Thickness (Mild Steel) | Key Features |

WSX NC30 | 1kW – 6kW | Stainless Steel, Mild Steel, Aluminum, Copper | Up to 12-16mm | High-speed motorized auto-focus, Anti-collision protection, Dust-proof design |

WSX NC63 | 3kW – 6kW | Stainless Steel, Mild Steel, Aluminum, Brass, Copper, Titanium | Up to 25mm | Efficient water cooling system, Enhanced beam collimation, Designed for ultra-thick metal cutting applications |

Tip: These models let you work with thin and thick materials. Your work is flexible and always reliable.

Project Efficiency

You make building projects faster by using automatic cutting machines. These machines work quicker than people. You finish jobs sooner and save money. Fiber cutters are very exact, so you plan better and waste less. You use smart software to arrange parts on sheets, so you use more of each piece.

Automatic machines help you make fewer mistakes.

You waste 10-15% less material than old ways.

Zero-tail cutting saves even more, up to 5-10%.

You spend less time fixing problems, so your team is faster.

You finish jobs faster and spend less money. You can try new ideas without waiting long. You get to be creative and test new designs. These machines help you give great results on time.

Note: Laser cutting machines help your team work smarter and waste less. You get better efficiency and more chances to try new designs.

You see how advanced cutting heads change many industries. Companies now finish jobs faster and save money.

Car makers cut production time by 37% and save millions each year.

Aerospace engineers build new parts in days, not weeks.

Fashion brands waste less material and keep designs consistent.

Metal shops make more parts with less labor.

Automation and AI help you get better results. Machines adjust settings in real time and spot problems quickly. Future systems will use robotics and smart software to make work even easier. You can boost your own business by choosing WSX Laser Cutting Heads.